Bioplastic Revolution: Reshaping Industrial Packaging

Sustainable packaging is transforming the industrial landscape, with bioplastics emerging as a game-changing solution. This innovative material, derived from renewable resources, is revolutionizing product protection and distribution across sectors. As businesses seek eco-friendly alternatives to traditional plastics, bioplastics offer a promising pathway to reduce environmental impact while meeting stringent packaging requirements.

The adoption of bioplastics in industrial packaging has been driven by several factors. First, the increasing awareness of plastic pollution and its detrimental effects on ecosystems has prompted businesses to seek more environmentally friendly alternatives. Second, government regulations and consumer demand for sustainable products have incentivized companies to invest in greener packaging solutions. Finally, advancements in bioplastic technology have improved the material’s performance, making it a viable option for a wide range of industrial applications.

Diverse Applications Across Industries

Bioplastics have found applications in various industrial sectors, demonstrating their versatility and adaptability. In the food and beverage industry, bioplastic packaging has been used for perishable goods, offering excellent barrier properties and biodegradability. The automotive sector has incorporated bioplastics into packaging for spare parts and components, reducing waste and improving the overall sustainability of their supply chains.

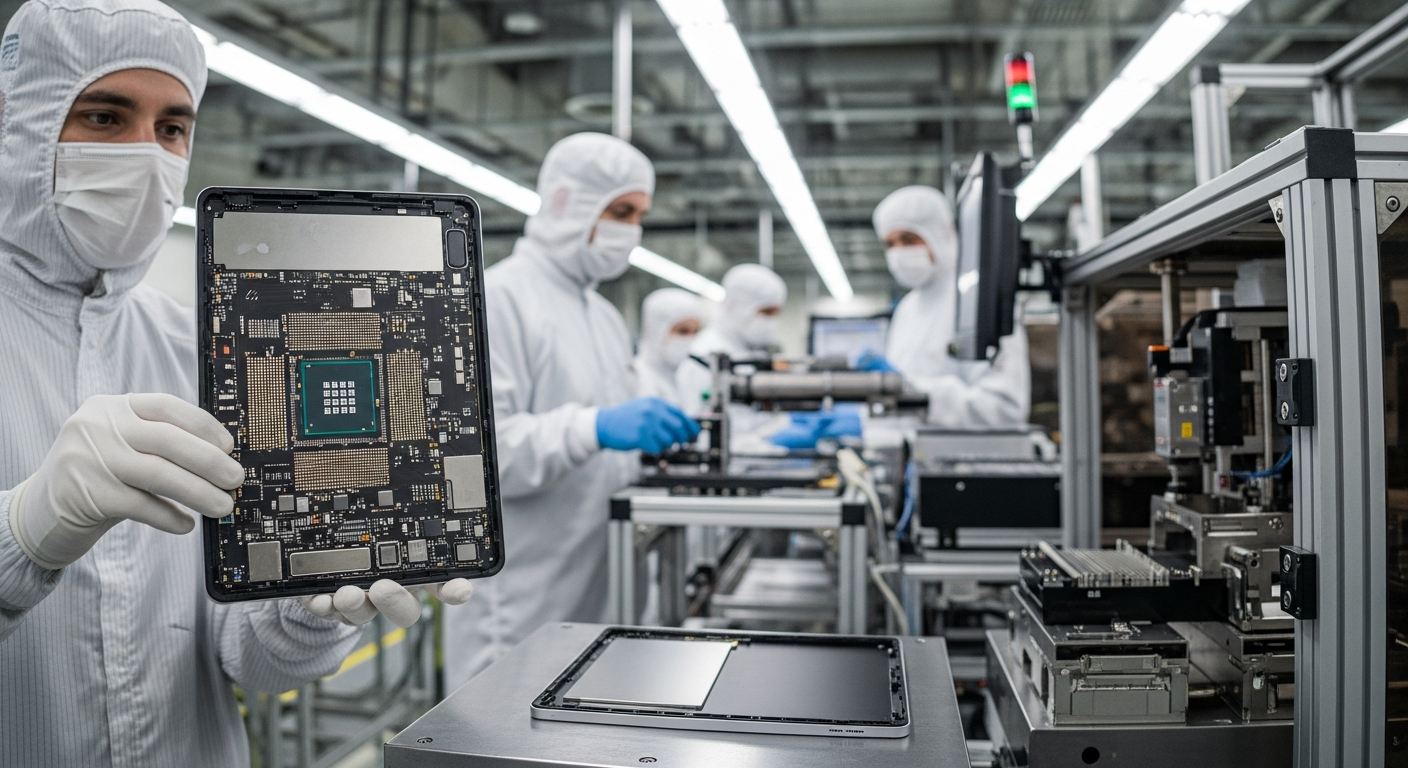

The electronics industry has also embraced bioplastics for packaging sensitive equipment, leveraging their shock-absorbing properties and static-free characteristics. In the pharmaceutical sector, bioplastic packaging has been utilized for drug delivery systems and medical devices, meeting stringent hygiene and safety standards while reducing environmental impact.

Performance and Durability

One of the key challenges in adopting bioplastics for industrial packaging has been ensuring that these materials meet the rigorous performance standards required in various applications. Manufacturers have made significant strides in improving the mechanical properties, barrier characteristics, and thermal stability of bioplastics, making them increasingly comparable to traditional plastics.

Recent innovations have led to the development of bioplastics with enhanced tensile strength, flexibility, and impact resistance, crucial for protecting products during transportation and storage. Additionally, advances in barrier technologies have improved the moisture and oxygen resistance of bioplastic packaging, extending the shelf life of perishable goods and sensitive materials.

Cost Considerations and Economic Viability

While the environmental benefits of bioplastics are clear, their adoption in industrial packaging has been influenced by economic factors. Initially, the production costs of bioplastics were significantly higher than those of conventional plastics, limiting their widespread use. However, as production scales up and technologies improve, the cost gap has narrowed considerably.

Many companies have recognized the long-term economic benefits of transitioning to bioplastic packaging. These include potential savings from reduced waste management costs, improved brand image, and increased market share among environmentally conscious consumers. Furthermore, as regulations around plastic use become more stringent, early adopters of bioplastic packaging may gain a competitive advantage and avoid potential penalties or restrictions.

Challenges and Future Outlook

Despite the promising advancements in bioplastic technology, several challenges remain in their widespread adoption for industrial packaging. One of the primary concerns is the availability of raw materials and the potential competition with food crops for agricultural resources. To address this, researchers are exploring alternative feedstocks, such as algae and agricultural waste, which could provide a more sustainable source of bioplastic materials.

Another challenge lies in the end-of-life management of bioplastic packaging. While many bioplastics are biodegradable or compostable, proper disposal infrastructure and consumer education are crucial to realizing their environmental benefits. Industry stakeholders are working to improve recycling and composting facilities to accommodate the growing use of bioplastics.

Looking ahead, the future of bioplastics in industrial packaging appears promising. Ongoing research and development efforts are focused on improving the performance, cost-effectiveness, and sustainability of these materials. As technology advances and production scales up, bioplastics are poised to play an increasingly significant role in reshaping the industrial packaging landscape, offering a more sustainable solution for businesses and the environment alike.

Actionable Strategies for Implementing Bioplastic Packaging

• Conduct a comprehensive lifecycle assessment of current packaging materials to identify opportunities for bioplastic substitution

• Collaborate with bioplastic suppliers to develop custom formulations that meet specific performance requirements

• Implement pilot programs to test bioplastic packaging in real-world conditions and gather data on performance and customer feedback

• Invest in employee training to ensure proper handling and disposal of bioplastic packaging materials

• Engage with customers and stakeholders to communicate the benefits of bioplastic packaging and gather insights for continuous improvement

In conclusion, the adoption of bioplastics in industrial packaging represents a significant shift towards more sustainable business practices. As technology continues to advance and awareness of environmental issues grows, bioplastics are poised to become an integral part of the packaging industry. By embracing this innovative solution, businesses can reduce their environmental footprint, meet regulatory requirements, and potentially gain a competitive edge in an increasingly eco-conscious market.