Digital Transformation in Manufacturing Processes

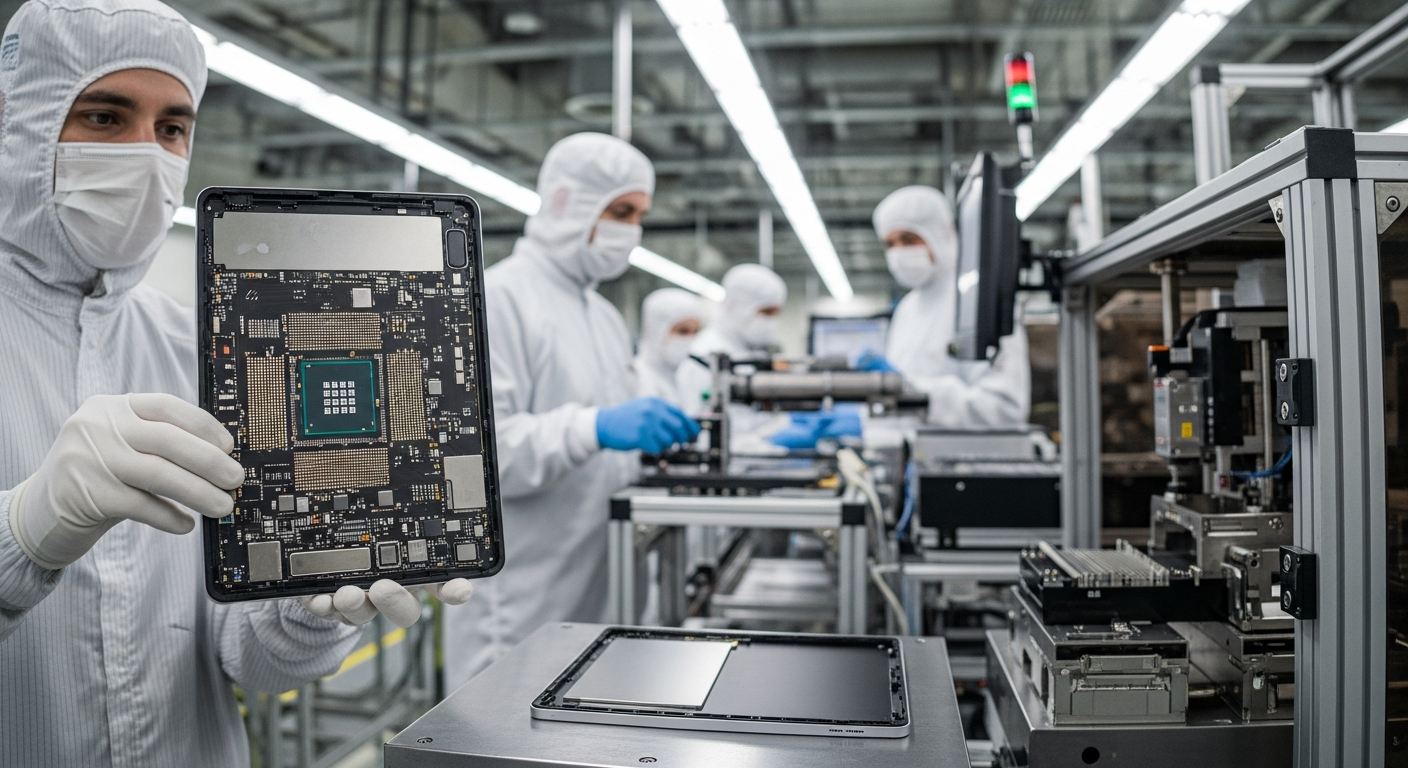

Digital transformation is reshaping the global manufacturing landscape, moving beyond mere technological adoption to encompass a holistic shift in operational paradigms. This evolution involves integrating advanced digital technologies into every facet of production, from initial design and raw material sourcing to final product delivery and customer engagement. Manufacturers worldwide are embracing this change to enhance efficiency, foster innovation, and maintain competitiveness in an increasingly dynamic market environment.

Understanding Digital Transformation in Manufacturing

Digital transformation in manufacturing represents a fundamental rethinking of how products are designed, made, and delivered. It involves the strategic integration of digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), cloud computing, and big data analytics into existing manufacturing processes. This goes beyond simply digitizing records; it’s about creating interconnected systems that enable real-time data exchange, automation, and intelligent decision-making across the entire value chain. The goal is to build more agile, responsive, and resilient manufacturing operations that can adapt quickly to market demands and unforeseen disruptions.

Enhancing Production and Operational Efficiency

At the core of digital transformation is the drive to elevate production and operational efficiency. Advanced automation, powered by robotics and AI, streamlines repetitive tasks, reduces human error, and accelerates production cycles. Predictive maintenance, a key benefit of IoT implementation, uses sensors to monitor equipment health in real-time, anticipating failures before they occur. This minimizes downtime, extends machinery lifespan, and optimizes maintenance schedules, directly impacting overall equipment effectiveness (OEE). Furthermore, digital twins, virtual replicas of physical assets or processes, allow manufacturers to simulate and optimize operations without disrupting actual production, leading to significant gains in efficiency.

Transforming Supply Chain and Logistics Management

Digital technologies are revolutionizing supply chain and logistics management, providing unprecedented transparency and control. Blockchain can secure and track transactions across the supply chain, ensuring authenticity and traceability of materials. AI-driven analytics optimize inventory levels, forecast demand more accurately, and identify potential bottlenecks or risks in the supply network. This enhanced visibility allows for proactive adjustments, improving resilience against global disruptions and ensuring timely delivery of goods. The integration of digital platforms facilitates seamless communication and collaboration with suppliers and partners, creating a more cohesive and efficient global supply network.

Fostering Innovation and Sustainable Growth

Digital transformation is a powerful catalyst for innovation and sustainable growth in manufacturing. By leveraging data analytics, companies can gain deeper insights into customer preferences, enabling the rapid development of new products and services tailored to market demands. Additive manufacturing (3D printing) allows for rapid prototyping and custom production, reducing material waste and enabling more intricate designs. Furthermore, digital tools support sustainability initiatives by optimizing resource consumption, minimizing waste, and tracking environmental impact across the production lifecycle. This strategic approach to technology adoption not only drives market growth but also positions manufacturers as environmentally responsible leaders.

The Role of Workforce and Data Analytics

The human element remains central to successful digital transformation. While automation handles routine tasks, a skilled workforce is essential for managing complex digital systems, interpreting data, and driving innovation. Investment in upskilling and reskilling programs ensures that employees are equipped with the necessary digital literacy and analytical capabilities. Data analytics, in particular, empowers decision-makers with actionable insights, transforming raw data into strategic intelligence. From optimizing shop floor layouts to personalizing customer experiences, data-driven management is crucial for unlocking the full potential of digital technologies and fostering a culture of continuous improvement.

Digital transformation is not merely a trend but a fundamental shift that is redefining the future of manufacturing. By strategically integrating advanced technologies across all operations, manufacturers can achieve unparalleled levels of efficiency, innovation, and sustainability. This comprehensive approach enables companies to navigate complex global markets, adapt to evolving customer expectations, and secure a competitive edge in the modern industrial landscape, ultimately driving long-term growth and resilience.