Emerging Technologies in Industrial Application

The industrial landscape is undergoing a significant transformation driven by the rapid adoption of emerging technologies. These advancements are reshaping traditional processes, enhancing operational efficiency, and paving the way for unprecedented levels of innovation across various sectors. From smart factories to optimized supply chains, the integration of cutting-edge solutions is creating more resilient, productive, and sustainable industrial environments globally. Understanding these technological shifts is crucial for businesses aiming to maintain competitiveness and foster long-term growth in a dynamic market.

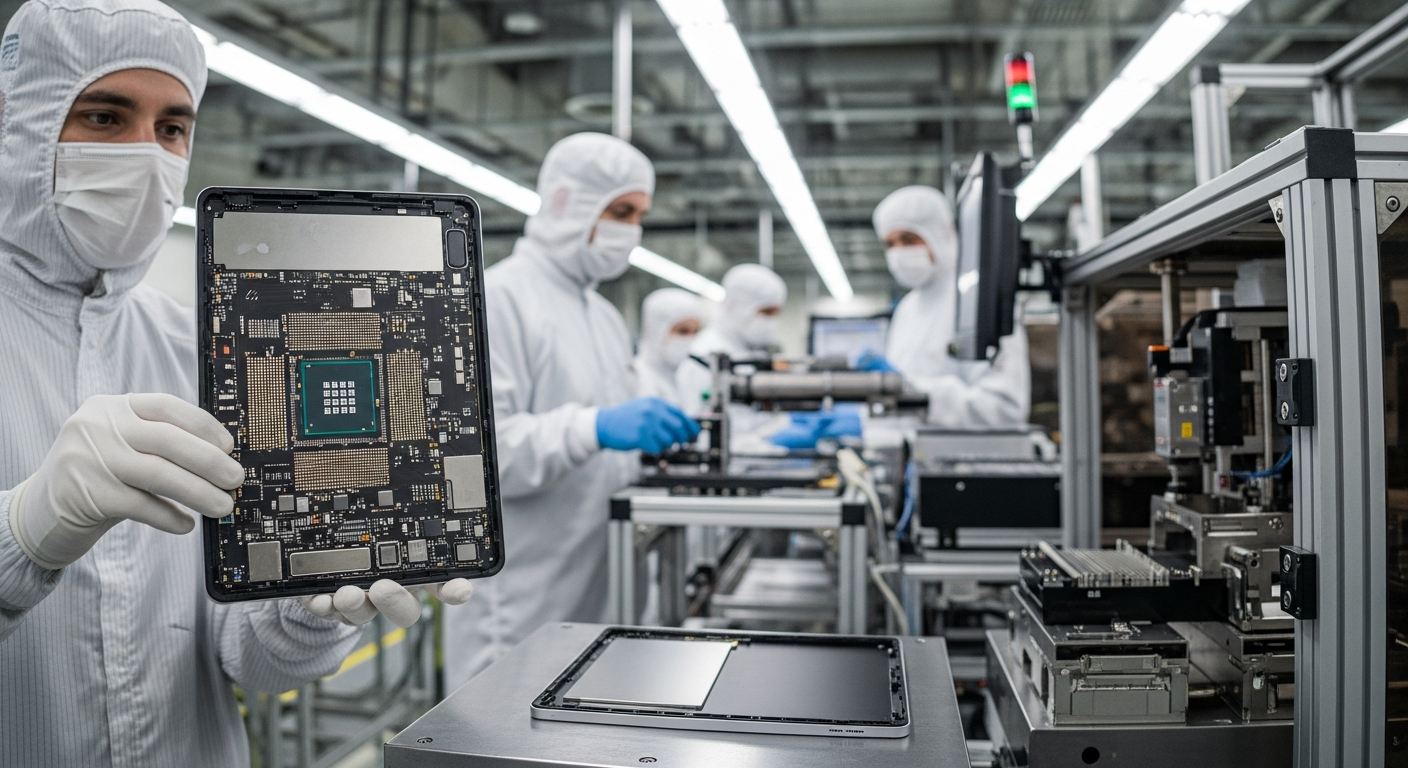

How are Manufacturing and Production Evolving with Technology?

Manufacturing and production processes are being fundamentally redefined by new technologies. The shift towards Industry 4.0, characterized by cyber-physical systems, the Internet of Things (IoT), and cloud computing, is enabling factories to become smarter and more connected. This evolution allows for real-time data collection and analysis, predictive maintenance, and highly customized production lines. Digital twins, virtual replicas of physical assets or processes, are also gaining traction, offering manufacturers the ability to simulate and optimize operations before implementation, thereby reducing risks and improving product development cycles. This integration of digital tools throughout the production lifecycle contributes significantly to enhanced output quality and reduced waste.

What Role Does Automation and Robotics Play in Modern Operations?

Automation and robotics are central to the modernization of industrial operations. Collaborative robots (cobots), which can work safely alongside human employees, are becoming more prevalent, taking on repetitive or hazardous tasks and freeing up the workforce for more complex, value-added activities. Advanced automation systems are not just about speeding up processes; they are also about precision, consistency, and reducing human error. In logistics, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are streamlining material handling and warehousing, improving inventory management and turnaround times. The continuous development in artificial intelligence (AI) and machine learning (ML) further enhances the capabilities of these automated systems, allowing them to adapt and learn from their environment.

How is Digital Transformation Impacting Industrial Efficiency?

Digital transformation is a comprehensive strategy that leverages digital technologies to create new or modify existing business processes, culture, and customer experiences to meet changing business and market requirements. For industrial efficiency, this means integrating data from various sources—sensors on machines, enterprise resource planning (ERP) systems, and supply chain platforms—into a unified digital ecosystem. Big data analytics provides actionable insights, enabling companies to identify bottlenecks, optimize resource allocation, and make data-driven decisions. Cloud computing offers scalable infrastructure for storing and processing vast amounts of data, facilitating access and collaboration across global operations. The result is a more agile, responsive, and efficient industrial enterprise capable of quickly adapting to market demands.

What are the Implications for Logistics and Supply Chain Management?

The implications of emerging technologies for logistics and supply chain management are transformative. Real-time tracking and monitoring capabilities, powered by IoT devices and advanced analytics, provide unprecedented visibility across the entire supply chain, from raw materials to final delivery. Blockchain technology is emerging as a tool to enhance transparency and traceability, creating immutable records of transactions and movements, which can help verify product authenticity and improve accountability. Predictive analytics helps forecast demand more accurately, optimize inventory levels, and anticipate potential disruptions, leading to more resilient and responsive global supply networks. This technological integration helps reduce operational costs, minimize delays, and improve customer satisfaction.

How does Innovation Drive Sustainability in Industrial Development?

Innovation is a key driver for sustainability in industrial development. New technologies are enabling industries to reduce their environmental footprint and operate more responsibly. For instance, advanced materials science is leading to the development of lighter, more durable, and recyclable materials, reducing resource consumption. Energy management systems, powered by AI and IoT, optimize energy usage in factories and buildings, leading to significant reductions in consumption and greenhouse gas emissions. Circular economy principles are being supported by technologies that facilitate better waste management, recycling, and remanufacturing processes. Furthermore, the development of cleaner production methods and renewable energy integration within industrial facilities underscores a global commitment to environmental stewardship and long-term ecological balance.

What is the Future of the Industrial Workforce and Enterprise?

The future of the industrial workforce and enterprise will involve a symbiotic relationship between humans and advanced technology. While automation handles routine tasks, the human workforce will increasingly focus on areas requiring creativity, critical thinking, complex problem-solving, and interpersonal skills. Continuous learning and upskilling will be essential for employees to adapt to new tools and processes. Enterprises are investing in digital training platforms and augmented reality (AR) tools to enhance employee training and on-the-job support. The traditional hierarchical structures are evolving into more collaborative and agile models, where cross-functional teams leverage technology to drive innovation and respond swiftly to market changes. This evolution aims to create more engaging, productive, and safer working environments.

The integration of emerging technologies is fundamentally reshaping the industrial landscape, driving unprecedented levels of efficiency, innovation, and sustainability. From smart manufacturing to optimized supply chains, these advancements are creating a more connected and responsive global industry. Businesses that embrace digital transformation, automation, and data-driven decision-making are better positioned to thrive in this evolving environment, fostering growth and resilience for the future.