Supply Chain Resilience in a Volatile Global Economy

The global economy is characterized by increasing volatility, making robust supply chain resilience an imperative for businesses worldwide. Disruptions, ranging from geopolitical tensions and trade policy shifts to natural disasters and public health crises, can severely impact operations, leading to significant financial losses and reputational damage. Developing a proactive and adaptive approach to supply chain management is crucial for maintaining continuity, mitigating risks, and ensuring sustained business growth in an unpredictable environment.

Understanding Supply Chain Vulnerabilities and the Need for Resilience

Modern supply chains are intricate networks, often spanning multiple continents and involving numerous stakeholders. This complexity, while offering opportunities for efficiency and cost reduction, also introduces inherent vulnerabilities. Geopolitical instability, sudden shifts in consumer demand, technological failures, and environmental events can all expose weaknesses. A lack of visibility across the supply chain, over-reliance on single suppliers, and insufficient inventory buffers are common factors that exacerbate these risks. Therefore, a comprehensive strategy for building resilience is not merely an option but a strategic necessity for businesses aiming to navigate the complexities of the global economy.

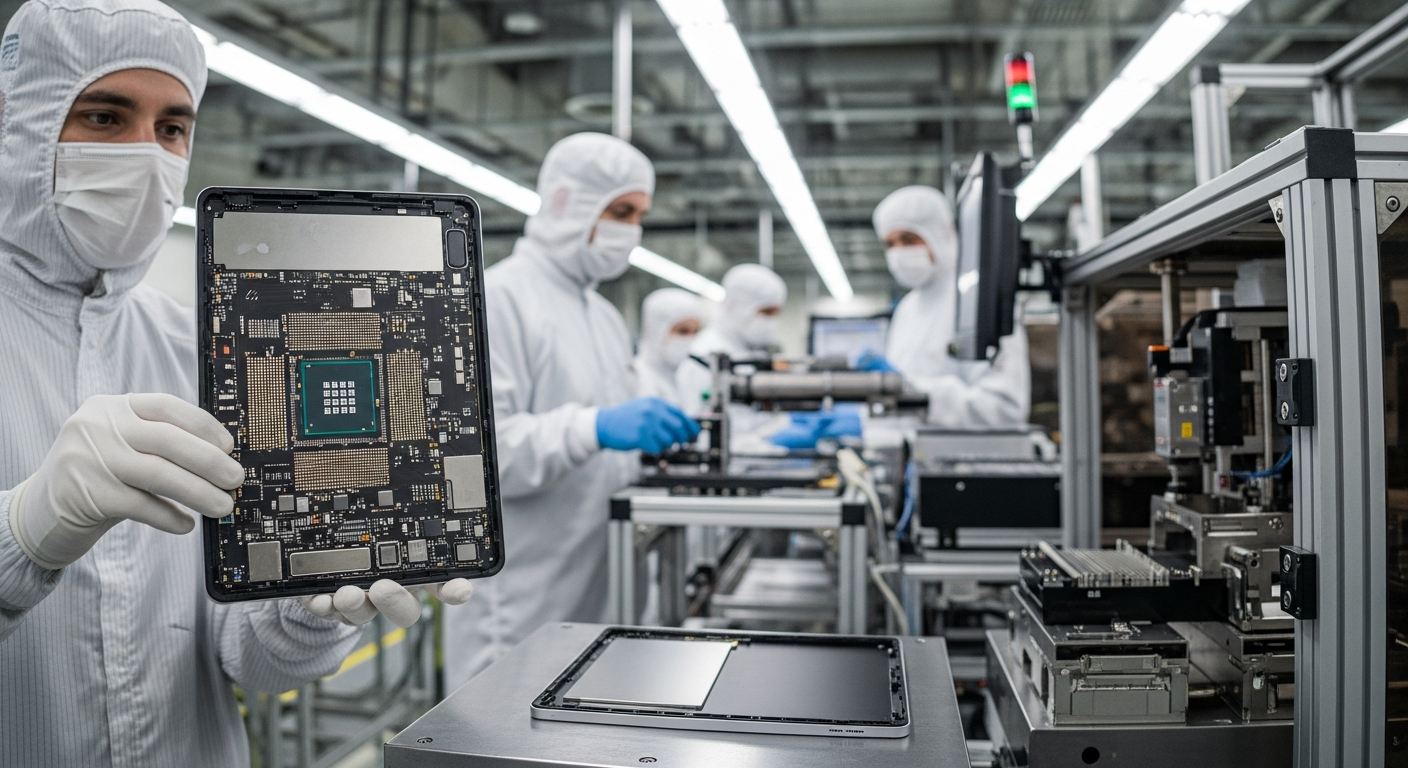

Leveraging Technology and Automation for Enhanced Operations

Technology plays a pivotal role in strengthening supply chain resilience. The adoption of advanced solutions, such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), can significantly enhance predictive capabilities and operational agility. Automation in logistics and production processes, from automated warehouses to robotic assembly lines, reduces reliance on manual labor, increases throughput, and improves accuracy. Furthermore, digital platforms and real-time analytics provide granular insights into inventory levels, transportation routes, and supplier performance, enabling quicker decision-making and proactive problem-solving to maintain efficiency.

Fostering Innovation and Sustainability in Manufacturing

Innovation is key to transforming traditional manufacturing processes into more adaptable and robust systems. This includes exploring new materials, modular product designs, and flexible production lines that can quickly reconfigure to meet changing demands or circumvent disruptions. Beyond immediate operational benefits, embedding sustainability practices within the supply chain contributes to long-term resilience. By focusing on ethical sourcing, reducing waste, and optimizing resource use, businesses can not only mitigate environmental risks but also enhance their reputation, attract conscious consumers, and comply with evolving regulations, fostering growth and development.

Developing a Resilient Workforce and Management Processes

While technology and automation are critical, the human element remains indispensable. A skilled and adaptable workforce is essential for managing complex supply chains and responding effectively to unforeseen challenges. Investing in training and upskilling programs ensures that employees are proficient in new technologies and capable of agile decision-making. Simultaneously, robust management processes are vital. This involves establishing clear communication channels, implementing effective risk management frameworks, and fostering a culture of continuous improvement across all operations. Regular scenario planning and stress testing can further prepare teams to handle various disruption types.

Investment Considerations for Supply Chain Resilience

Building a resilient supply chain often requires significant upfront investment, but the long-term benefits in terms of reduced risk, improved efficiency, and sustained growth typically outweigh these costs. Investments can range from upgrading technology infrastructure and implementing automation solutions to developing new supplier relationships and enhancing workforce capabilities. The cost will vary widely based on the scale of the organization, the complexity of its existing supply chain, and the specific solutions being adopted. It’s a strategic expenditure aimed at protecting future revenue streams and market position.

| Investment Area | Typical Scope | Estimated Cost Range (USD) |

|---|---|---|

| Supply Chain Software | ERP, SCM, WMS, TMS, Predictive Analytics platforms | $50,000 - $5,000,000+ |

| Automation Hardware | Robotics, Automated Guided Vehicles (AGVs), Sensors | $10,000 - $1,000,000+ per unit/system |

| Data & Analytics Services | Implementation, Customization, Support, Data Scientists | $20,000 - $500,000+ annually |

| Workforce Training | Reskilling, Upskilling for Digital Tools | $5,000 - $50,000+ per program |

| Consulting Services | Strategy Development, Risk Assessment, Implementation | $30,000 - $1,000,000+ per project |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, achieving supply chain resilience in a volatile global economy demands a multi-faceted approach. By strategically integrating technology, fostering innovation, prioritizing sustainability, and empowering a capable workforce, businesses can transform vulnerabilities into sources of competitive advantage. This proactive stance not only mitigates risks but also positions organizations for continuous growth and adaptability in an ever-changing world.