Vehicle Recycling Innovations for a Circular Economy

The automotive industry is increasingly recognizing the importance of sustainable practices, leading to significant advancements in vehicle recycling. As the global fleet continues to grow, integrating circular economy principles into vehicle design, manufacturing, and end-of-life management becomes crucial. These innovations aim to minimize waste, recover valuable resources, and reduce the environmental footprint associated with vehicle production and disposal, paving the way for a more resource-efficient future.

Enhancing Sustainability Through Advanced Materials Recycling

The pursuit of a circular economy in the automotive sector centers heavily on improving the sustainability of materials used in vehicle construction. Traditional recycling methods often involve shredding, which can lead to contamination and downcycling of materials. Modern innovation focuses on advanced sorting and separation techniques, such as optical sorting for plastics and chemical processes for composite materials, ensuring higher purity levels for recycled content. This allows for the reintegration of materials like high-strength steel, aluminum, and various polymers back into new vehicle components, reducing the reliance on virgin resources and conserving energy in the manufacturing process.

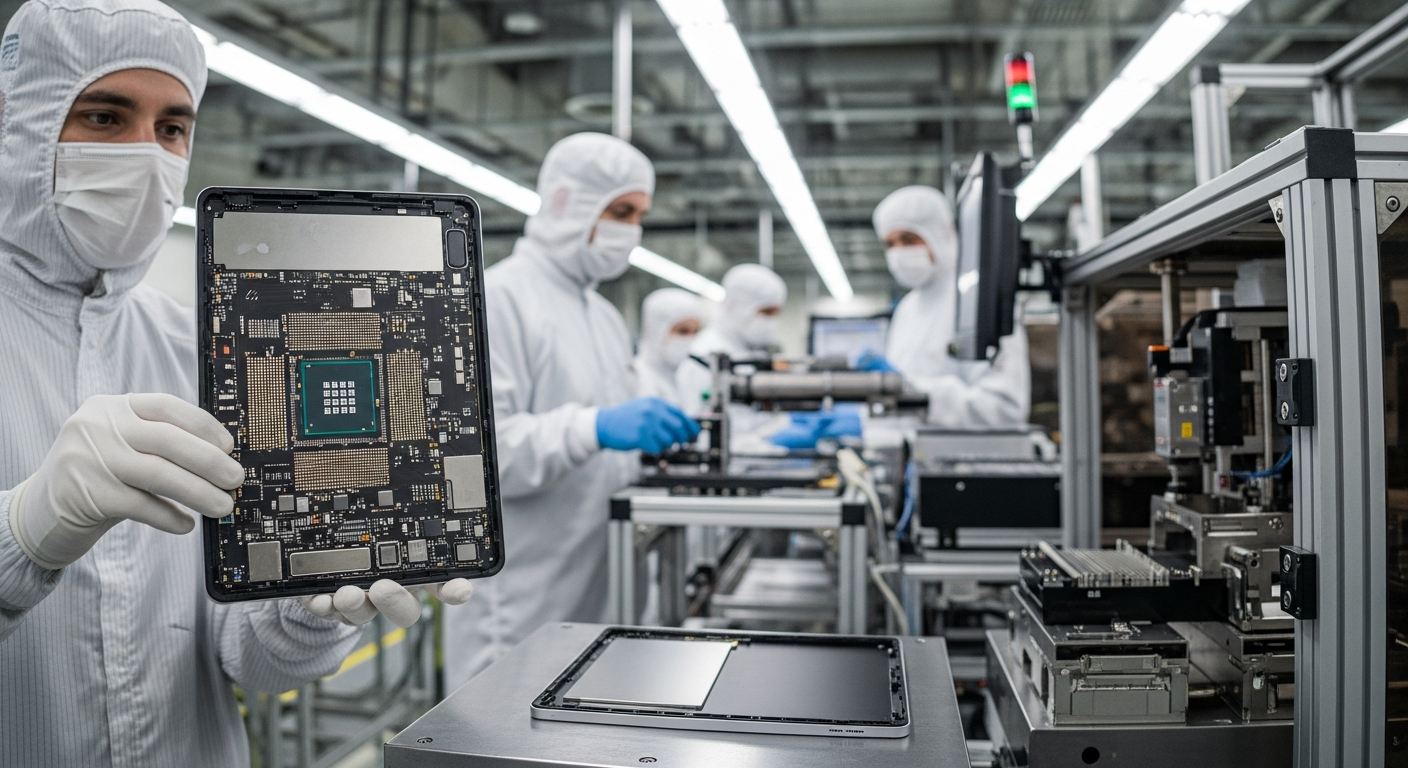

Technology and Innovation in Vehicle Disassembly

Technology plays a pivotal role in transforming vehicle end-of-life processing. Automated disassembly lines, often utilizing robotics and artificial intelligence, are becoming more prevalent. These systems can precisely identify and remove specific components, such as airbags, fluids, and valuable electronic modules, before the main body is processed. Digital scanning and imaging technologies help in material identification, optimizing the sorting process for different grades of metals and plastics. This level of precision not only improves material recovery rates but also enhances the overall efficiency and safety of recycling operations, minimizing human exposure to hazardous materials.

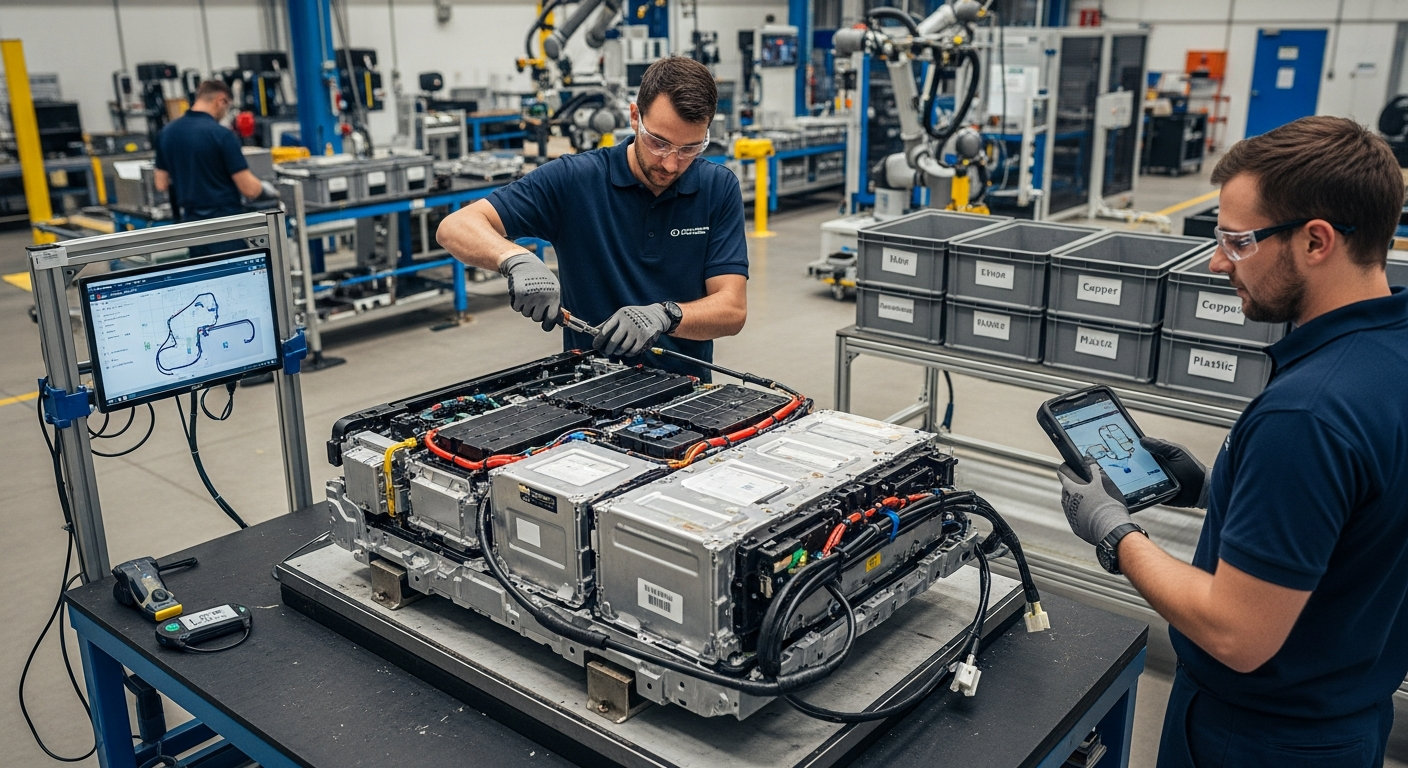

Recycling Electric Vehicle Batteries and Associated Systems

With the rapid growth of electric vehicles (EVs), the recycling of their batteries and complex systems presents a unique challenge and opportunity. EV batteries contain valuable and often rare materials like lithium, cobalt, and nickel, which are critical to recover. Innovations in battery recycling include hydrometallurgical and pyrometallurgical processes, designed to extract these materials with high recovery rates. Beyond the cells themselves, the associated power electronics and connectivity systems also require specialized handling to ensure all valuable components are reclaimed and hazardous substances are managed responsibly. Developing robust infrastructure for EV battery collection and processing is essential for future mobility.

Engineering Principles for Circular Vehicle Design

Achieving a truly circular economy requires a fundamental shift in vehicle design and engineering philosophies. Manufacturers are increasingly adopting ‘design for disassembly’ and ‘design for recycling’ principles. This involves using fewer material types, simplifying assembly methods, and employing modular components that can be easily removed, repaired, or replaced. For instance, using single-material plastics where possible or designing components with clear material labels facilitates their identification and separation at the end of the vehicle’s life. Such thoughtful design reduces the complexity and cost of recycling, making it more economically viable and environmentally beneficial.

The Future of Mobility and Sustainable Transport

The integration of advanced recycling practices into the automotive lifecycle has profound implications for the future of mobility and transport. By maximizing resource utilization and minimizing waste, these innovations contribute to a more resilient and sustainable industry. A circular approach reduces the environmental impact of vehicle production, from mining raw materials to energy consumption in manufacturing. Furthermore, it fosters a paradigm where vehicles are not merely products but a collection of valuable resources that can be continuously cycled, supporting global efforts towards carbon reduction and resource security. This holistic view ensures that as transport evolves, it does so with environmental stewardship at its core.

Advanced vehicle recycling innovations are crucial for establishing a circular economy within the automotive sector. By focusing on sustainable material recovery, leveraging technology for efficient disassembly, addressing the unique challenges of electric vehicle components, and embedding circularity into vehicle design, the industry is moving towards a more resource-efficient and environmentally responsible future. These efforts collectively contribute to a more sustainable transport ecosystem, ensuring that the benefits of mobility are balanced with ecological preservation.